In the world of panel cutting, precision and efficiency are paramount. The HUAHUA CNC beam saw machine stands out as a powerful tool that combines advanced technology with ease of use to enhance cutting operations in various industries. Let’s explore its features in more detail.

Easy Operation with the Industrial PC Control System

The HUAHUA CNC beam saw machine is equipped with an intuitive industrial PC control system. This user-friendly interface allows for manual editing of cutting plans, making it easy to adjust settings on the fly. The system also boasts simulation capabilities, ensuring that operators can visualize cuts before execution. Moreover, the integration with barcode and factory automation software streamlines the workflow, allowing seamless communication across the production process.

High-Precision Pneumatic Clamping for Damage-Free Cutting

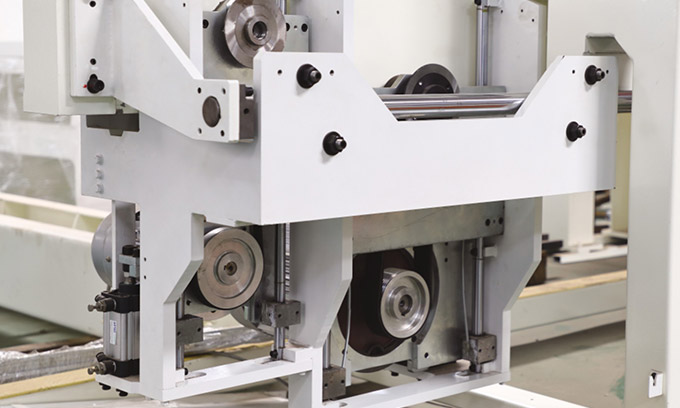

One of the standout features of the HUAHUA CNC beam saw machine is its two-finger pneumatic clamping structure. This system enhances cutting accuracy by securely holding panels in place while preventing surface damage. The air cylinder clamping mechanism ensures a strong, even grip on materials, contributing to smooth and precise cuts. Additionally, the roller conveyor plays a crucial role in feeding panels accurately and smoothly, further boosting the machine’s overall performance.

Reliable Saw Carriage Drive with Servo Motor Technology

The HUAHUA CNC beam saw machine is powered by a 2kW servo motor that provides robust cutting power. This motor works in conjunction with a gear and power reducer system, ensuring stable performance even under heavy loads. High-efficiency servo motors are known for their low energy consumption, making them a cost-effective solution for manufacturers. The result is a reliable and efficient cutting process that maximizes both speed and precision.

Conclusion

In conclusion, the HUAHUA CNC beam saw machine combines advanced features that enhance operational efficiency and cutting accuracy, making it an excellent choice for businesses looking to improve their panel-cutting processes.