Automated systems have become integral to modern industrial operations, and the principles behind them are grounded in engineering fundamentals. For companies like WEIGHT SORTING, grasping the core functionality of a sorter machine is essential for appreciating its role in quality and efficiency. This equipment executes a precise electromechanical process to categorize items based on predefined physical criteria.

Phase One: Product Induction and Singulation

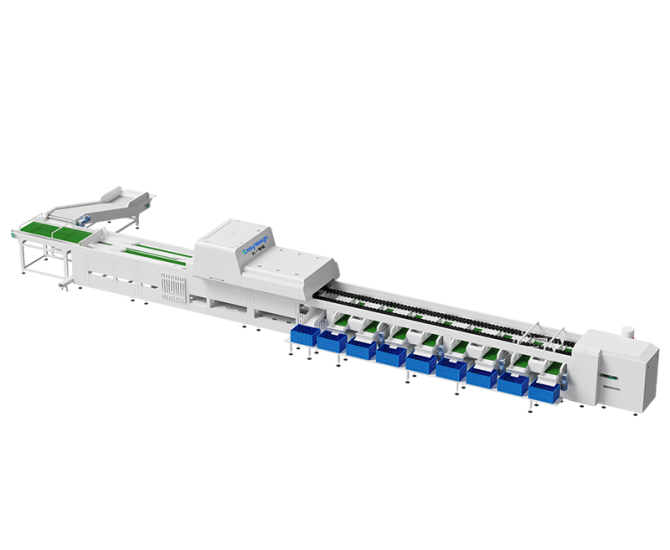

The process initiates with the induction of products onto the conveying system. Items are fed onto the sorter machine in a manner that promotes singulation, ensuring they are spaced and oriented correctly for accurate individual analysis. This initial stage is critical, as it prepares each unit for the precise measurement that follows, preventing overlapping or misaligned items that could cause downstream errors.

Phase Two: In-Line Data Acquisition and Analysis

Following induction, each item passes through a detection zone, typically a scanning tunnel or over a specialized platform. Here, integrated sensors capture specific physical data. For a sorter machine utilized by WEIGHT SORTING, this involves highly accurate load cells that measure mass. This data is instantly relayed to a central processing unit, which compares the reading against preset acceptance parameters programmed by the operator.

Phase Three: Directed Divergence and Ejection

The final phase is the physical action based on the processor’s decision. Once an item is classified, the control system activates a rejection mechanism. This mechanism, which could be an air jet, a push arm, or a deflector, is timed precisely to engage as the item reaches the appropriate diversion point on the conveyor. Accepted items continue along the primary path, while outliers are channeled to a separate lane for further handling.

This three-phase framework transforms a simple conveyor into an intelligent classification system. The method provides manufacturing and packaging facilities with a reliable, data-driven process for product standardization, directly impacting quality control and operational throughput.